Press Release

Contribute to lower power consumption in server with High efficiency, High airflow Cooling Fan Motor Drive Control.

Nuvoton Releases Industrial 48V Direct drive Motor driver IC

Kyoto, Japan, JULY 8, 2024 - Nuvoton Technology Corporation Japan (NTCJ) announced today the launch of a new 48V direct drive motor driver IC that enables high efficiency and high airflow with high speed rotation in fan motors.

Achievements

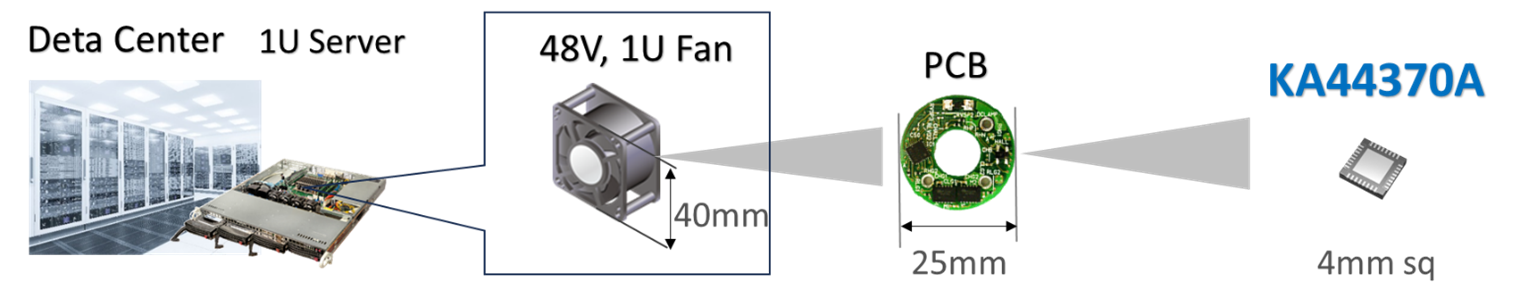

- Realizing a 100V-rated high-speed, high-output circuit capable of direct 48V drive on a small chip, and the chip is assembled in a QFN package [1] that can be mounted on a 48V 1U (unit) [2] fan motor (size 40mm x 40mm), contributing to lower power consumption in 1U servers and higher density in server racks.

- Unique current feedback control technology realizes low power consumption and low vibration at high speed, which was conventionally challenging for single-phase fan motor, and consequently expands the airflow range.

- Stable and reliable motor start-up is possible even in the case of mutual interference when multiple fan motors are used, or when reverse rotation of the fan motor occurs due to unexpected external airflow.

In addition, the penetration of AI servers appeals for even higher data processing capabilities, and limited space in data center facilities demands for slim 1U servers that can further increase the density of server racks. Therefore, server fan motors should be capable of both 48V direct driven and 1U in size. Furthermore, as data processing speeds increases, the fan motors are rotating at a higher speed to cool the heat generated by CPUs and GPUs. At the same time, it is necessary to suppress the rising trend of power consumption in fan motor, and its vibrations that have negative impact on the HDD error rate.

NTCJ launches a new motor driver IC that is compatible with the server's 48V power supply system and this 48V direct drive chip is assembled in a small package that can be mounted on a 1U fan motor.

Product details

https://www.nuvoton.com/products/motor-drivers/motor-driver-ics/brushless-dC-Motor-drivers-BLDC/Features

- The 48V direct drive is compatible with the 48V power supply system in server, realizing low power consumption in data center. In addition, the chip of the motor driver is assembled in a small QFN package, contributing to the higher density of the server rack.

- The unique current feedback control technology realizes low power consumption and low vibration, and consequently expands the range of airflow at high-speed rotation, which was challenging for single-phase fan motors that typically have large motor torque fluctuations.

- Stable and reliable motor start-up is possible even in the case of mutual interference when multiple fan motors are used, or when reverse rotation takes place due to external airflow.

The newly developed motor driver IC incorporates a 100V-rated voltage control circuit based on the high-voltage control circuit technology that NTCJ has cultivated over the years into a small 4mm x 4mm QFN package, while significantly reducing external components such as step-down regulators (53% reduction from the conventional 24V product). This reduces power loss and enables the installation onto 1U size (40mm x 40mm) fans, contributing to high-density data processing.

The high-speed data processing of the AI server requires the fan motor to rotate at a higher speed in order to cool down the increasing heat generation. Simultaneously, it is necessary to suppress the rising trends of the power consumption in fan motors, and its vibrations that adversely affect the HDD error rate.

NTCJ’s proprietary technology for real-time feedback control of motor drive current value and phase with high resolution makes it possible to reduce the power consumption of single-phase fan motors by 30% and vibration by 20 dB compared to conventional motors, even at high speeds when higher airflow can be output. This contributes to high-speed, large-capacity data processing that requires high cooling capabilities.

In general, it is difficult to detect reverse rotation in a single-phase fan motor, so when the fan motor stops and there are interference in between multiple fans, or when the fan motor rotates in reverse due to disturbances such as the inflow of external air, it is difficult to restart the fan motor in conventional products. However, our proprietary rotation control algorithm can achieve reliable and stable restart even from reverse rotation speed that is twice as high as the conventional products.

Applications

Servers, Base stations, FA equipment, and other industrial equipment

Product name

Industrial 48V direct drive motor driver IC

KA44370A

Specification

| Product No. | KA44370A |

|---|---|

| Absolute maximum rated voltage | 100V |

| Absolute maximum rated current | + / - 100mA (driven by external FET Nch+Nch) |

| Input IF | PWM / VSP |

| Output IF | FG / LD |

| Package | HQFN32 (4mm × 4mm) |

Example

Start of mass production

July 2024

Contact Us

Media contact

Corporate Strategy Office, Nuvoton Technology Corporation Japan

NTCJ_PR@nuvoton.com

Technical contact

Marketing Department, Battery and Analog Solution Business Group, Nuvoton Technology Corporation Japan

NTCJ_mkt_Battery_Analog@nuvoton.com

Definitions

- [1]QFN package

- [2]1U

Quad Flat Non lead package, 4-way leadless small and thin package.

1 U (unit) is approximately 44.45 mm in pitch unit, as the mounting height on the rack specified in the EIA standard.

About Nuvoton Technology Corporation Japan

Nuvoton Technology Corporation Japan (NTCJ) joined Nuvoton Group in 2020. As a dedicated global semiconductor manufacturer,NTCJ provides technology and various products cultivated over 60 years since its establishment, and solutions that optimally combine them.We value relationships with our customers and partners, and by providing added value that exceeds expectations, we are working as a global solution company that solves various issues in society, industry, and people's lives. For more information, please visit https://www.nuvoton.co.jp/en/.

The names of organizations, companies, products, or services mentioned in this press release are registered trademarks or trademarks of their respective companies or organizations. The information provided is current as of the date of publication and is subject to change without prior notice. Please be aware of this.